|

What Is a Motor Oil?

The four primary purposes of a motor oil are lubrication of all moving internal engine parts to minimize friction and wear, cooling the engine, contamination and corrosion control, and sealing the piston rings and other mating surfaces.

A motor oil is made up of two basic components: base stock and additives. The base stock makes up the majority of the completed oil. The functions of the base stock include lubrication of internal moving parts, heat removal and sealing piston rings. Motor oil base stocks can be made from: 1) Petroleum, 2) one or several synthetic chemicals, 3) a combination of synthetics and petroleum (called para-synthetic, partialsynthetic or synthetic-fortified). A motor oil is made up of two basic components: base stock and additives. The base stock makes up the majority of the completed oil. The functions of the base stock include lubrication of internal moving parts, heat removal and sealing piston rings. Motor oil base stocks can be made from: 1) Petroleum, 2) one or several synthetic chemicals, 3) a combination of synthetics and petroleum (called para-synthetic, partialsynthetic or synthetic-fortified).

A petroleum base stock consists of many different oil fractions blended together to form the final product. Some of these fractions will "boil off" at relatively low temperatures. Generally, molecules of a petroleum base stock are long carbon chains which are sensitive to the stress of heat. Engine temperatures encourage these chains to break down, changing the physical properties (such as viscosity) of the motor oil.

A synthetic base stock is generally composed of uniformly shaped molecules that are resistant to the stress of heat. AMSOIL Synthetic Motor Oils exhibit a very low "boil off" rate. There are no excessively long carbon chains in their structure to break down and alter the physical properties (such as viscosity) of the oil.

The functions of the additive system include anti-wear, anti-foam, corrosion protection, acid neutralization, maintenance of viscosity, detergency and dispersancy. The additive system is composed of various chemicals that do these specific jobs. Their quality varies widely throughout the lubrication industry, ranging from a bare minimum in some oils (to just meet certain requirements) to exceptionally high quality, as in all AMSOIL Motor Oils.

Improvements in Oil

Motor oils today are vastly different from motor oils 30 years ago. Because of new demands placed on lubricants due to modern engine design, today's oils must meet stringent requirements in areas of viscosity, wear protection, corrosion protection, acid neutralization, detergency and dispersancy. Variations in these factors determine which service classification rating and viscosity grade an oil receives.

Viscosity

One of the most important properties of an oil is its Viscosity. This refers to the internal cohesiveness of the oil or its resistance to flow. An oil must be able to flow at low temperatures to lubricate internal moving parts upon starting an engine. An oil must also remain viscous or "thick" enough to protect an engine at high operating temperatures.

Viscosity Index Improvers are additives that extend a multi-grade motor oil's viscosity range. Viscosity Index (VI) indicates an oil's viscosity characteristics over a wide temperature range. The less an oil's viscosity changes with temperature changes, the better the oil protects the engine. An oil that changes little with temperature changes receives a high VI and an oil that changes greatly with temperature changes receives a low VI. Better oils have high VIs.

The VI is measured by comparing the viscosity of the oil at 40�C (104�F) with its viscosity at 100�C (212�F). It does not indicate the performance of an oil at low or high temperatures.

Cold Temperature Protection

Pour Point refers to the temperature at which an oil has solidified, due to cold temperatures, and can no longer pour. The Cold Crank Simulator measures the speed at which a shaft can turn in cold-thickened oil and evaluates the "startability" of the oil. An engine must be able to reach a turning speed above 300 rpms for the engine to start. The Mini-Rotary Viscometer measures the speed at which a shaft can turn in cold-thickened oil and evaluates the "flowability" of the oil. An oil must flow to the oil pump inlet to be circulated through the engine for lubrication and wear protection. The results of the Cold Crank Simulator and Mini-Rotary Viscometer are used to assign an oil's SAE "W" grade. In multi-grade or multi-viscosity oils such as 10W-30 and 10W- 40, chemical additives called Pour Point Depressants are often added to the oil to allow it to flow enough at cold temperatures for the oil pump to be able to circulate the oil to all parts of the engine.

Volatility

Petroleum multi-viscosity oils have various chemical ingredients in them that allow them to protect engines in a wide range of temperatures. Some of these ingredients are used to keep the oil flowing when it is cold. However, these ingredients are very volatile, and through their normal use in an engine (especially when it is hot), these ingredients evaporate, or boil off. Lighter fractions of a petroleum base stock also boil off in heat, which changes the viscosity of the remaining oil. The oil left behind in the crankcase is thicker and doesn't flow easily when it's cold. This thick oil can take up to five minutes to freely circulate in a cold engine after starting it. Meanwhile the engine is being starved of oil and not being protected against friction and wear.

Wear Protection

One of an oil's main functions is to lubricate moving parts to prevent friction and wear. The oil forms a thin film on, around and between parts which work in close proximity with one another. Ideally, a constant flow of oil keeps those parts from rubbing together. Metal to metal contact creates tremendous frictional and thermal forces that can actually weld moving parts together, causing the engine to seize. Today's modern oils do a very good job of preventing engine seizure once the engine has warmed up. At start-up, however, when there is little oil on moving parts to lubricate them, metal to metal contact can occur. A good motor oil contains: Anti-wear Additives to protect engines by bonding to metal surfaces and forming a protective layer between moving parts. This layer does not prevent their rubbing together but minimizes the effects of contact.

Oxidation

Oxidation is the chemical breakdown of oil due to the extreme heat in the engine. Oil oxidation can cause acidic gasses and sludge to form in the crankcase. Acidic gasses combine with water in the crankcase to corrode and rust the engine. Corrosion is especially critical in diesel engines.

To counteract the effects of acids, neutralizing additives are blended into motor oil. An oil's neutralizing capability is expressed by its Total Base Number (TBN). Most oils for diesel engines in North America have a TBN between 7 and 10, which is sufficient for the sulfur content of diesel fuels found here. AMSOIL manufactures a diesel oil with a TBN of 12. A typical TBN for a gasoline engine motor oil is 5 or 6.

Detergents and Dispersants

Combustion causes carbon buildup and deposit formation on the pistons, rings, valves and cylinder walls. Carbon and deposits affect engine temperature, oil circulation, engine performance and fuel efficiency. Additionally, some combustion by-products slip past the piston rings and end up in the motor oil. These by-products can clog the engine's oil channels.

Detergents are added to the oil to keep the engine clean. They prevent the build-up of carbon or deposits from burned and unburned fuel and even from the oil itself.

Dispersants are added to prevent the agglomeration of sludge and dirt in the oil. Dispersants hold the dirt particles in suspension rather than allowing them to come together and form deposits. The particles suspended in the oil are eventually removed by the oil filter.

Foaming

Tiny air bubbles are constantly being "whipped" into motor oil by the action of many rapidly moving parts inside the engine. The result is a mass of oily froth called Foam. This foam has very little capacity to lubricate or aid in the cooling of the engine. It is important to minimize foaming in motor oil. The addition of silicone or other compounds in very small amounts makes most oils adequately foam-resistant.

Seal Swell

All motor oils must be compatible with the various seal materials used in engines. Oil must not cause seals to shrink, crack, degrade or dissolve. Ideally, oil should cause seals to expand or "swell" slightly to ensure continued proper sealing.

All AMSOIL Motor Oils exhibit excellent seal compatibility with Fluorocarbons, Buna-N, Silicone, Viton and other commonly used seal materials.

Heat Dispersal

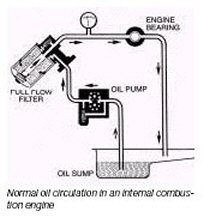

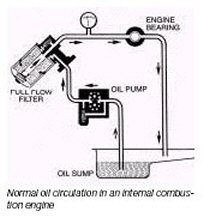

Motor oil helps cool the engine. The radiator/anti-freeze system is responsible for only 60 percent of the engine cooling that takes place. This cools only the upper portion of the engine, including the cylinder heads, cylinder walls and valves.

The other 40 percent is cooled by the oil. The oil is directed onto hot surfaces, such as the crankshaft, main and connecting rod bearings, the camshaft and its bearings,the timing gears, the pistons and many other components in the lower portion of the engine that directly depend on the motor oil for cooling.

Engine heat is created from both friction of moving parts and the ignition of fuel inside the cylinder. Oil carries heat away from these hot surfaces as it flows downward and dissipates heat to the surrounding air when it reaches the crankcase.

The amount of oil required to lubricate an engine is actually very small when compared to the amount needed to ensure proper cooling of these internal parts.

The oil pump constantly circulates the oil to all vital areas of your engine.

Classification Systems

Oil is classified according to two systems. One system determines the oil's viscosity (the SAE grade), and one system determines its performance level, i.e. which oil to use in what type of engine (the API class).

I. SAE Grade

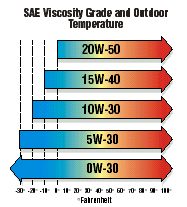

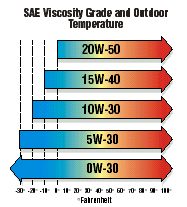

The Society of Automotive Engineers (SAE) Viscosity Grade is a system based on viscosity measures taken from a variety of tests. This system established eleven distinct motor oil viscosity classifications or grades: SAE0W, SAE5W, SAE10W, SAE15W, SAE20W, SAE25W, SAE20, SAE30, SAE40, SAE50 and SAE60. These are known as single grade or single viscosity oils.

These grades correspond to specific ranges that the particular oil falls into. The "W" in the classification indicates that the grade is suitable for use in cold temperatures. (You can think of the "W" as standing for "Winter.") The classifications increase numerically, allowing you to tell the difference between them and what this difference means. In simple terms, the lower the number, the lower the temperature at which the oil can be used for safe and effective protection. The higher the number, the better protection offered for high heat and high load situations.

Single grade oils have a limited range of protection and so have a limited number of uses. In order to increase an oil's usefulness, it must be able to meet the requirements of two or more classifications. Multigrade or multi-viscosity oils effectively meet the viscosity requirements of two or more classifications. Examples of multi-viscosity oils are SAE5W-30, SAE10W-30, SAE15W-40 and SAE20W-50. The number with a "W" focuses on an oil's properties at low temperatures. The number without a "W" characterizes properties at high temperatures. A multiviscosity or multi-grade oil, e.g. 10W-30, meets the 10W criteria when cold and the 30 criteria once hot. SAE10W-30 and SAE5W-30 are widely used because under all but extremely hot or cold conditions, they are light enough for easy engine cranking at low temperatures, and heavy enough to protect satisfactorily at high temperatures. Single grade oils have a limited range of protection and so have a limited number of uses. In order to increase an oil's usefulness, it must be able to meet the requirements of two or more classifications. Multigrade or multi-viscosity oils effectively meet the viscosity requirements of two or more classifications. Examples of multi-viscosity oils are SAE5W-30, SAE10W-30, SAE15W-40 and SAE20W-50. The number with a "W" focuses on an oil's properties at low temperatures. The number without a "W" characterizes properties at high temperatures. A multiviscosity or multi-grade oil, e.g. 10W-30, meets the 10W criteria when cold and the 30 criteria once hot. SAE10W-30 and SAE5W-30 are widely used because under all but extremely hot or cold conditions, they are light enough for easy engine cranking at low temperatures, and heavy enough to protect satisfactorily at high temperatures.

II. API Class

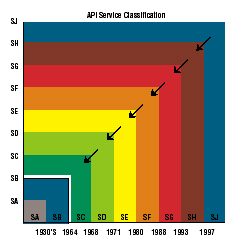

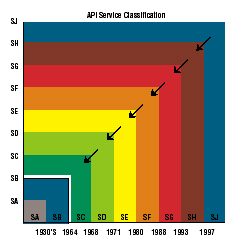

The American Petroleum Institute (API) developed a classification system to identify oils formulated to meet the operating requirements of various engines. The API system has two general categories: S-series and C-series.

The S-series service classification emphasizes oil properties critical to gasoline or propane fueled engines. If an oil passes a series of tests in specific engines (API Sequence tests), the oil can be sold bearing the applicable API service classification.

There are ten S-series classifications: SA, SB, SC, SD, SE, SF, SG, SH, SJ, and SL The S-series classifications progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it, with SL currently offering the most protection. SL oil may be used in any engine, unless the engine manufacturer specifies a "non-detergent" oil. progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it, with SL currently offering the most protection. SL oil may be used in any engine, unless the engine manufacturer specifies a "non-detergent" oil.

SA and SB are nondetergent oils and are not recommended for use unless specified. SC oils were required for new car warranties from 1964 to 1967. SD oils were required from 1968 to 1970 and a few in 1971. Some new car warranties required SE oils in 1971 and its use continued through 1979. New car warranties from 1980 to 1989 require SF oils. New car warranties from 1990 to 1993 require SG oils.

New car warranties beginning with the 1994 model year require oils with an API SH performance rating. New car warranties beginning with 1997 require an API SJ oil. The year 2001 brought the introduction of SL oils. SL oils are designed to increase fuel economy, reduce emissions and protect hot, hard-working engines over the course of a very long warranty period.

C-series classifications deal with diesel engines. There are eight classifications: CA, CB, CC, CD, CD-II, CE, CF-4 and CG-4. CH-4, CA, CB, CC and CD performance rated oils are no longer used in diesel engines. However, oils used in turbocharged gasoline engines retain CF as part of their performance designation: SH, CF.

Unlike S-series classifications, C-series classifications do not supersede one another. The current classifications, CF, CF-2 and CH-4, are specified for various applications.

CF for Indirect Injected Diesel Engine Service. Service Category CF denotes service typical of indirect injected diesel engines and other diesel engines which use a broad range of diesel fuels in off-road applications, including diesel fuel with greater than 0.5 percent sulfur by weight. CF oils may be used in place of CD oils.

CF-2 for Two-Stroke Diesel Engine Service. Service Category CF-2 denotes service typical of two-stroke engines requiring highly effective control over cylinder and ring-face scuffing and deposits. CF- 2 oils may be used in engines for which CD-II oils are recommended.

CH-4 for Severe Duty Diesel Engine Service. Service Category CG-4 denotes service typical of high speed four-stroke diesel engines used in heavy-duty on- and off-highway applications. CH-4 oils are especially effective in engines designed to meet 1998 exhaust emission standards. CH-4 oils may be used in place of CD, CE, CF-4 and CG-4 oils.

The SAE and API classification systems are intended to help motorists choose the right oil for their needs. The choice depends on the engine, the outdoor temperature and the type of driving the motorist does most. Most motorists are more familiar with the SAE Viscosity Grade system than they are with the API Class system.

SJ is the current API class. SJ oils are widely available and most gasoline engine automobiles either specify SJ oil or, if they were manufactured before the SJ class was created, may use SJ oil. However, one should be sure to purchase SJ class oil for the best engine protection available. Of course, motorists should follow the oil specification of their vehicle owner's manual.

Turbocharged Engines

Turbocharged engines (both gasoline and diesel) are different from conventional combustion engines and thus have different lubrication requirements.

A turbocharger compresses incoming air, then feeds this compressed air into the intake manifold, packing a higher density air to fuel mixture, which upon combustion can yield as much as 10 to 20 percent more horsepower.

The smaller engines being turbocharged in some contemporary cars run at higher RPMs than normal engines do. Higher RPMs require a higher quality oil because more stress is placed on the engine.

Turbo engines run much hotter than normal engines run. Heat causes three main problems for lubricating oil. First, wear-promoting viscosity losses are their most damaging in heat. Second, there is more carbon build-up and deposit formation with the higher heat, reducing the car's performance and efficiency. Third, oxidation occurs more rapidly at higher temperatures, which increases corrosion.

Because turbocharged engines run so hot, they should be idled to cool the turbo bearing and the oil before the engine is shut off. If the engine is shut off without cooling the turbo bearing and oil, the oil undergoes heat soak, a long period of exposure to very high heat. Heat soak is extremely harmful to oil. The more volatile portions of the oil boil off and what oil is left oxidizes to form a crusty layer inside the turbocharger. This crust will eventually flake off, wedge between close-fitting components in the turbocharger, and grind and gouge surfaces, altering clearances and generating more abrasive debris. Eventually, this condition leads to the total destruction of the turbocharger, requiring costly repair or replacement.

To combat these problems, a turbo oil of API service classification "CF" is required. API CF turbo oils should have high quality VI Improvers, so there won't be a breakdown in viscosity performance. CF oils specify higher detergent levels to help keep the engine free of carbon build-up and deposit formation. In addition, increased levels of anti-oxidants protect the engine from oxidation and corrosion problems.

SJ-CF oils are appropriate for use in turbocharged gasoline engines. They are not appropriate for use in diesel engines, though the "CF" may make it appear so.

The API Service Category designation for diesel engine oils begins with the "C" listing, for example, CH-4, SH. Because fleets often simplify maintenance practices by allowing use of one oil for all fleet vehicles, diesel engine oils are sometimes formulated for use in gasoline engines. Such oils earn a designation such as CH-4, SH. Such oils provide adequate performance in gasoline engines though they are primarily formulated for use in heavyduty diesels.

On the other hand, most gasoline engine oils are used in non-fleet vehicles so they are not required to pull "double duty" as both gasoline and diesel engine lubricants. They are not formulated with the special needs of heavy-duty diesel engines in mind. Oils whose API Service Category begins with an "S" listing are meant for use in gasoline engines only. The "CF" in the SH, CF designation indicates sufficient detergency and oxidation protection for turbo-charged gasoline engines.

Always follow recommended SAE and API standards in your engine owner's manual to be assured of proper protection for your engine.

The Importance of Engine Filtration and Maintenance

Engine Wear

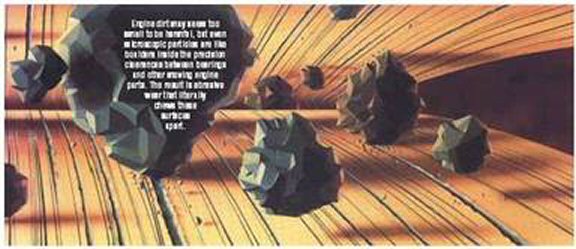

Automotive experts agree that dirt is the number one cause of engine wear. Federal-Mogul Corporation, in analyzing the cause of engine bearing failure, indicates that 43.4 percent of all engine bearing distress is caused by dirt.

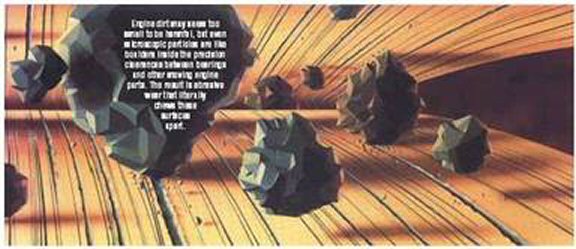

Engine dirt particles are so small -mere dust specks - and an engine is a highly sophisticated piece of machinery, crafted from the most durable metal alloys. How can these minute particles bring down such a high-tech giant? crafted from the most durable metal alloys. How can these minute particles bring down such a high-tech giant?

The answer lies in the fact that dirt particles are extremely abrasive. They consist of razor-like flakes of road dust and airborne grit drawn into the engine through the intake.

manifold, as well as manufacturing scarf and wear metal particles generated inside the engine. These particles are carried by the oil into the precision clearances between bearings and other moving parts. Once they work in between these parts, they grind and gouge surfaces, altering clearances and generating more abrasive debris. As this wear cycle continues, precision components become sloppy and fatigued. Finally, they fail altogether.

Filtration is the key to preventing costly repairs caused by engine dirt. Filtration removes contaminants by trapping and holding them outside the system of oil circulation. In order for a filter to be truly effective, it must be able to capture contaminants of all types and sizes. AMSOIL has developed a complete line of sophisticated filtration products designed to offer the best protection available against virtually all harmful engine contaminants.

Air Filtration

An engine "breathes" air to mix with fuel for combustion - about 9,000 gallons of air for every one gallon of gas. And there is a lot more dust and grit in the air than is generally realized - over 400 tons of suspended dirt in a cubic mile of air over a typical city, and the concentration can be much higher in rural areas where there is frequent travel over unpaved roads.

The air filter is the first line of defense against the abrasive airborne grit that can cause serious damage inside an engine. But in order to do the job right, an air filter must effectively filter the dangerous particles out of the incoming air without obstructing the vital flow of air that sustains the engine.

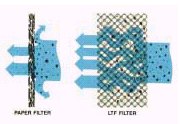

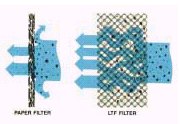

Conventional air filters use pleated paper as the filter media. The paper surface quickly becomes obstructed with dirt, reducing engine air intake. Inadequate air intake inhibits combustion, leading to poor engine performance and low fuel efficiency.

AMSOIL uses thick layers of polyurethane foam in its 2-Stage Air Filter construction. This foam is wetted with a light coating of "tack" oil. As air is drawn through the honeycomb network of oiled fibers, dirt particles are trapped by the oil and only clean air emerges from the foam and passes into the engine. AMSOIL uses thick layers of polyurethane foam in its 2-Stage Air Filter construction. This foam is wetted with a light coating of "tack" oil. As air is drawn through the honeycomb network of oiled fibers, dirt particles are trapped by the oil and only clean air emerges from the foam and passes into the engine.

Because the foam is much thicker than paper, the filtering area is more spread out and air is able to pass through it easily and quickly.

The Last Air Filter Your Car Will Ever Need

The AMSOIL 2-Stage Foam Air Filters are designed to last indefinitely with proper service. Under normal driving conditions they may be used for 25,000 miles or one year, then cleaned, reoiled, reinstalled and used again for thousands of additional miles of trouble-free service.

When a paper filter is full of dirt, the only option you have is to throw it away and replace it with a new one. This can be costly over several years because recommended change intervals can be relatively short depending on driving conditions.

Oil Filtration

Full-flow oil filters install directly into the line of oil circulation. The "fullflow" of oil passes through the filter as the oil journeys between the oil pump and the engine. Full-flow oil filters install directly into the line of oil circulation. The "fullflow" of oil passes through the filter as the oil journeys between the oil pump and the engine.

A full-flow filter must be capable of removing and holding contaminants without obstructing oil flow to the engine. In order to achieve this, most filters on the market compromise the filtration of finer particles by using a thin layer of porous filter paper. In addition, these filters have almost no extended cleaning ability since they have a low capacity for storing dirt.

These "surface-type" paper filters quickly become restricted as debris builds up on the paper surface. When this happens, the filter by-pass valve opens and the filter begins to allow unfiltered oil into the engine.

The AMSOIL SDF Engine Oil Filter is composed of a special cellulose, synthetic and glass blend media to provide longer life and improved efficiency. Performance tests demonstrated that AMSOIL SDF Filters provide up to 100 percent more capacity than other leading filters. They also achieve nearly 95 percent operating efficiency, outperforming all major brands. An oil pressure relief valve assures proper oil flow at all times under all operating conditions. Each heavy-duty case has a drawn steel double-crimp at the base with rolled-under seaming. An anti-drain back valve keeps dirty oil in the filter when the engine is not running.

By-Pass Oil Filtration

An average full flow filter traps particles as small as 20 microns. The filter cannot remove finer particles because the oil must be filtered quickly while removing most of the particles present in the oil. the oil must be filtered quickly while removing most of the particles present in the oil.

However, particles in the 5 to 20 micron range cause up to 60% of all engine wear. The AMSOIL By-Pass Oil Filter traps particles in the 5 to 20 micron range. In fact, the AMSOIL By-Pass Oil Filter traps particles smaller than 1 micron.

Unlike the full-flow filter, a bypass filter is situated outside the main line of oil circulation. The bypass filter taps into the main line, bleeding off and cleaning only a portion of the oil at any one time. The by-pass filter retains the oil longer and does a thorough job of removing contaminants without the worry of obstructing oil circulation.

The AMSOIL By-Pass Filter traps particles smaller than one micron in diameter, leaving oil analytically clean and free from harmful dirt particles. And even though the AMSOIL By-Pass Filter only draws about 10% of the oil in the system at one time, it will filter all the oil in a six-quart system in about five minutes (at an engine speed equivalent to 45 miles per hour).

Water Removal

Engines accumulate water from intake air and from fuel combustion. Water promotes rust and corrosion in engines. Water also reacts with oil additives and reduces additive effectiveness. Water is particularly harmful in cars that are not driven often. Engines accumulate water from intake air and from fuel combustion. Water promotes rust and corrosion in engines. Water also reacts with oil additives and reduces additive effectiveness. Water is particularly harmful in cars that are not driven often.

The unique composition of the AMSOIL By-Pass filtering media allows for the removal of water from the engine oil. Even water that has been thoroughly churned into the oil by mechanical agitation is separated and safely stored in the cartridge, or filter element, eliminating the risk of oil degradation and engine rust and corrosion.

Reduces Oil Changes

By cleaning the oil so completely, the AMSOIL By-Pass Oil Filter prolongs not only engine life but also the life of the oil itself. With the AMSOIL By-Pass Oil Filter, oil changes can be extended well beyond normal, in many cases indefinitely, depending upon the conditions and severity of use. the oil itself. With the AMSOIL By-Pass Oil Filter, oil changes can be extended well beyond normal, in many cases indefinitely, depending upon the conditions and severity of use.

Dual Remote: Patented Protection

Available only from AMSOIL, the Dual Remote Oil Filtration System replaces your conventional full flow filter, mounting in any convenient location in your engine, and gives you full flow and bypass oil filter protection. With Dual Remote, filter changes are quick, clean and easy. And Dual Remote increases your engine's oil capacity, helping your oil work better, not harder.

Oil Analysis

By analyzing used engine oil, a qualified lab can determine the degree of protection the oil is delivering and make certain the oil has not been contaminated. Oil analysis can also detect impending engine failure.

The AMSOIL TRIGARD Plan offers motorists AMSOIL Synthetic Motor Oil, AMSOIL Oil and Air Filters and oil analysis for their personal vehicles, such as passenger cars or motorhomes. The AMSOIL G-1318 and G-1451 offer oil analysis for heavy duty diesel engines in commercial use. They may also be used for passenger car oil analysis. Oil analysis helps motorists derive the longest life from their AMSOIL Synthetic Motor Oil and from their engine.

|

|

A motor oil is made up of two basic components: base stock and additives. The base stock makes up the majority of the completed oil. The functions of the base stock include lubrication of internal moving parts, heat removal and sealing piston rings. Motor oil base stocks can be made from: 1) Petroleum, 2) one or several synthetic chemicals, 3) a combination of synthetics and petroleum (called para-synthetic, partialsynthetic or synthetic-fortified).

A motor oil is made up of two basic components: base stock and additives. The base stock makes up the majority of the completed oil. The functions of the base stock include lubrication of internal moving parts, heat removal and sealing piston rings. Motor oil base stocks can be made from: 1) Petroleum, 2) one or several synthetic chemicals, 3) a combination of synthetics and petroleum (called para-synthetic, partialsynthetic or synthetic-fortified).  Single grade oils have a limited range of protection and so have a limited number of uses. In order to increase an oil's usefulness, it must be able to meet the requirements of two or more classifications. Multigrade or multi-viscosity oils effectively meet the viscosity requirements of two or more classifications. Examples of multi-viscosity oils are SAE5W-30, SAE10W-30, SAE15W-40 and SAE20W-50. The number with a "W" focuses on an oil's properties at low temperatures. The number without a "W" characterizes properties at high temperatures. A multiviscosity or multi-grade oil, e.g. 10W-30, meets the 10W criteria when cold and the 30 criteria once hot. SAE10W-30 and SAE5W-30 are widely used because under all but extremely hot or cold conditions, they are light enough for easy engine cranking at low temperatures, and heavy enough to protect satisfactorily at high temperatures.

Single grade oils have a limited range of protection and so have a limited number of uses. In order to increase an oil's usefulness, it must be able to meet the requirements of two or more classifications. Multigrade or multi-viscosity oils effectively meet the viscosity requirements of two or more classifications. Examples of multi-viscosity oils are SAE5W-30, SAE10W-30, SAE15W-40 and SAE20W-50. The number with a "W" focuses on an oil's properties at low temperatures. The number without a "W" characterizes properties at high temperatures. A multiviscosity or multi-grade oil, e.g. 10W-30, meets the 10W criteria when cold and the 30 criteria once hot. SAE10W-30 and SAE5W-30 are widely used because under all but extremely hot or cold conditions, they are light enough for easy engine cranking at low temperatures, and heavy enough to protect satisfactorily at high temperatures.  progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it, with SL currently offering the most protection. SL oil may be used in any engine, unless the engine manufacturer specifies a "non-detergent" oil.

progress alphabetically as the level of lubricant performance increases. Each classification replaces those before it, with SL currently offering the most protection. SL oil may be used in any engine, unless the engine manufacturer specifies a "non-detergent" oil. crafted from the most durable metal alloys. How can these minute particles bring down such a high-tech giant?

crafted from the most durable metal alloys. How can these minute particles bring down such a high-tech giant? AMSOIL uses thick layers of polyurethane foam in its 2-Stage Air Filter construction. This foam is wetted with a light coating of "tack" oil. As air is drawn through the honeycomb network of oiled fibers, dirt particles are trapped by the oil and only clean air emerges from the foam and passes into the engine.

AMSOIL uses thick layers of polyurethane foam in its 2-Stage Air Filter construction. This foam is wetted with a light coating of "tack" oil. As air is drawn through the honeycomb network of oiled fibers, dirt particles are trapped by the oil and only clean air emerges from the foam and passes into the engine. Full-flow oil filters install directly into the line of oil circulation. The "fullflow" of oil passes through the filter as the oil journeys between the oil pump and the engine.

Full-flow oil filters install directly into the line of oil circulation. The "fullflow" of oil passes through the filter as the oil journeys between the oil pump and the engine. the oil must be filtered quickly while removing most of the particles present in the oil.

the oil must be filtered quickly while removing most of the particles present in the oil. Engines accumulate water from intake air and from fuel combustion. Water promotes rust and corrosion in engines. Water also reacts with oil additives and reduces additive effectiveness. Water is particularly harmful in cars that are not driven often.

Engines accumulate water from intake air and from fuel combustion. Water promotes rust and corrosion in engines. Water also reacts with oil additives and reduces additive effectiveness. Water is particularly harmful in cars that are not driven often. the oil itself. With the AMSOIL By-Pass Oil Filter, oil changes can be extended well beyond normal, in many cases indefinitely, depending upon the conditions and severity of use.

the oil itself. With the AMSOIL By-Pass Oil Filter, oil changes can be extended well beyond normal, in many cases indefinitely, depending upon the conditions and severity of use.